POST-SILICON VALIDATION chine post-silicon validation Introduction: The Necessity for Post-Silicon Validation With modern SoCs becoming ever larger and more complex, their validation for correct functionality becomes critical for successful market placement.

Noting that the development of a chip from design to mass production in the semiconductor industry is very “complicated”, Zhu pointed out that the process takes a lot of stages of strict testing. Post-silicon validation is a very important step where it is checked whether the well-fabricated chip works perfectly as expected. This is done to make sure the chip does not act up under real in-system operation. Post-silicon validation becomes thus a very tough challenge for today’s complex semiconductor designs, especially as artificial intelligence (AI) and machine learning (ML) accelerators are increasingly integrated.

As a leading provider in semiconductor test solutions, PulseWave Semi knows this and has ‘leveraged’ the AI-based debugging engines on its post-silicon validation offerings. With the use of these advanced techniques, post-silicon validation engineers can discover and recover bugs in a more expedited manner that results in shortened time-to-market for high-quality, dependable products.

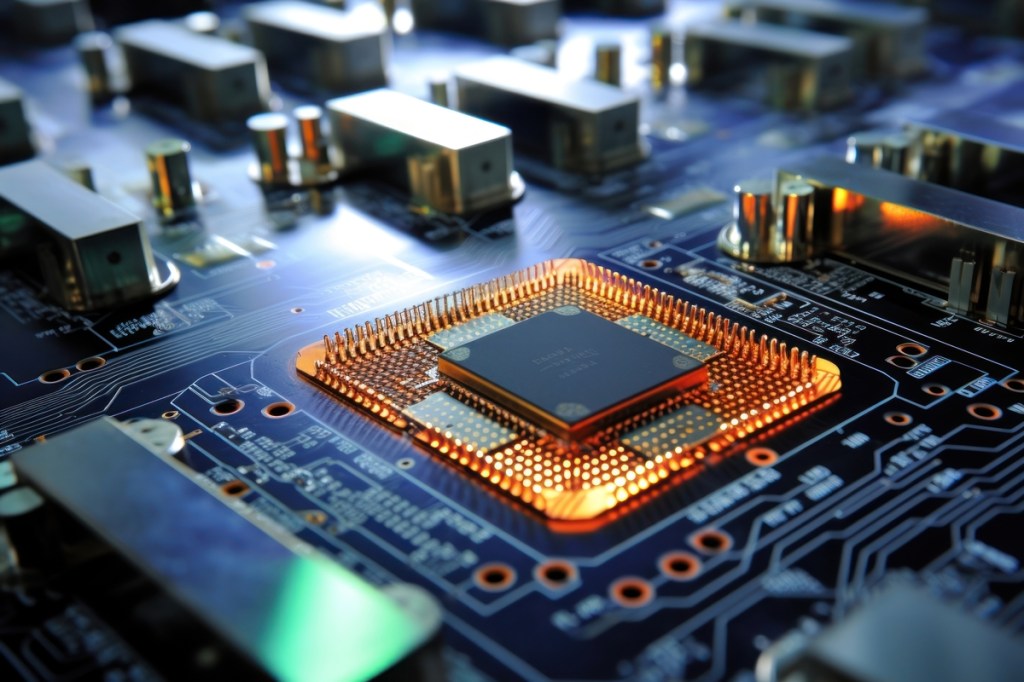

What is Post-Silicon Validation?

Post-silicon validation this is the process of testing recently produced silicon chips. It is the last stage before chips are sent out to customers or introduced into products. The major aim is to spot problems in real use that could not be held in check during presilicon simulation. This includes functional problems, performance limitations, power consumption issues, and system integration issues.

Traditionally, Real-world environment It has always been considered a challenge to create a realistic real-world like test environment for post silicon validation. Engineers subsequently subject the chip to a range of tests that seek to spot any imperfections in the chip’s behaviour and if any errors are found these are traced back to the design or manufacturing stage and are fixed.

AI in Post-Silicon Validation

Traditional debugging approaches are no longer adequate as the complexity of semiconductor design grows. The huge amount of data generated in post-silicon validation makes human inspection of all candidate issues in a chip’s performance impracticable. This is where debugging powered by AI could be a game changer.

AI and machine learning algorithms can be used to process the data from tests and recognize trends, as well as predict failures better than a human engineer. By having the debug work done automatically, it now allows for post-silicon validation engineers to work on solving the real hard problems rather than having to go through the data. This not only accelerates the process of validation but also enhances fault detection accuracy, guaranteeing a product of the best quality.

How AI-Driven Debugging Works

AI-based debugging uses machine learning models to crunch through huge amounts of test data that was created during post-silicon validation. These models are both trained on historical data from past validation, which enables them to identify patterns and anomalies that might suggest underlying problems.

- Data Preprocessing: Prior to being able to perform any analysis, the data resulting from post-silicon validation has to be prepared. That includes cleaning the data, eliminating noise, and arranging it into a form that AI algorithms can use. Some preprocessing such as data normalization and feature extraction is usually performed.

- Machine Learning Algorithms: When the data is ready, machine learning techniques, such as decision trees, neural networks and clustering algorithms, can now be applied to find correlations between different test conditions and chip performance. They are able to identify trends, and predict possible failures that would go unnoticed when done manually.

- Pattern Recognition: AI models have the greatest strength in pattern recognition of the data. To take a simple example, if certain conditions or chains of events cause a given part of the chip to fail, then AI can identify these patterns and highlight them for deeper analysis by post-silicon validation engineers.

- Root Cause Analysis: After troubleshooting, AI can help engineers troubleshoot and drill down to the root cause at the component level. By connecting errors to particular design or fabrication steps, AI could assist engineers in figuring out the precise reason a failure happened — whether it was because of hardware or software.

Key Benefits of AI for Debugging in Post-Silicon Validation

- Faster Debugging: The AI-based debugging can help reduce post-silicon-validation debugging time substantially. By automating data analysis, AI enables engineers to concentrate on solutions rather than getting lost in huge piles of test data. This results in accelerated time-to-market of semiconductors.

- Improved Accuracy: By being able to detect problems that may be too subtle for human engineers to see, machine learning algorithms will be also aware of patterns of degradation. This results in improved accuracy of error detection, and reduces the chance of bugs making their way through the validation stages and in to the market.

- Cost Savings: With faster debugging and better fault detection such cost savings are meaningful for semiconductor manufacturers. If the time for manual debugging can be shortened and the number of defects to be addressed post production can be reduced, the overall validation costs can be lessened.

- Scalability: The need to scale validation efforts has become increasingly important with the growth in complexity of semiconductor designs. The AI-powered debugging makes it possible for enterprises like PulseWave Semi to manage enormous amounts of test data, and for them to validate more complicated chips without scaling up their resources.

PulseWave Semi has been a leading AI-based Post-silicon Validation Services prior. The firm’s AI-based debugging platform automates the end-to-end validation flow, from first testing to root cause analysis.

Unique Chip AI Models In-House

PulseWave Semi collaborates with its customers to develop custom machine learning models tailored to address the specific problems that arise in their chip designs. They are trained on the client’s actual test data so that super accurate debugging and fault detection is made possible.

Real-Time Data Analysis

PulseWave Semi’s approach is based on real time analysis of data that gives engineers immediate feedback as they validate the process. This enables problems to be detected and corrected in real time as opposed to post-analysis, thereby dramatically shortening the time required for validation.

Collaboration with Post-Silicon Validation Engineers

Although AI can automate much of the flow of validation, human expertise is an essential part. PulseWave Semi’s AI-powered platform collaborates with post-silicon validation engineers by offering actionable intelligence and recommendations. This cooperation means that engineers can concentrate on addressing more complex problems, leaving the AI to take care of the simpler ones.

Integration with Existing Validation Infrastructure

Emulato – AI-Powered Emulation and Validation solving heavyweight bugs PulseWave Semi’s AI-Powered Debugging reduces the CPU power consumption at a backplane, but its AI-model requires a large memory space. This enables businesses to leverage AI-powered insights without changing their entire testing infrastructure.

Challenges and Considerations in AI-Powered Debugging

AI based debugging has many advantages, as well as its own challenges.

- Data Quality and Quantity: Artificial intelligence algorithms need an abundance of reliable data to operate properly. Poor or noisy data may result in incorrect predictions and detection of faults.

- Model Accuracy: Artificial intelligence models require the right type of data to be trained on in order to produce accurate predictions. If the model is trained with poor data, false positives and defects might be missed.

- Integration with Legacy Systems: Some businesses may have difficulty incorporating AI-powered debugging tools into their current validation infrastructure, especially if their infrastructure is built on legacy systems that were not created with AI in mind.

- Over-Reliance on AI: AI can automate much of the debugging process, but human expertise is required. Employees need to collaborate with AI to read results and ultimately, decide on the fix for whatever snafu was detected.

Conclusion

Post silicon validation with AI-based debugging is transforming the semiconductor industry. With machine learning and AI at the core, companies such as PulseWave Semi offer validation services that are faster, more accurate, and cost-effective. The involvement of AI in PSS validation will increasingly be critical to ensure the reliable operation as semiconductor designs become more complex. Leveraging the power to automatically mine through piles of data, uncover faint patterns, and forecast anomalies in the making, AI-powered debugging changing the way chips are tested and verified, so that only flawless products are delivered to the market.

At PulseWave Semi, the integration of AI with post-silicon validation services is the future of semiconductor testing – faster, smarter, and more dependable than ever.

Leave a comment